Feature

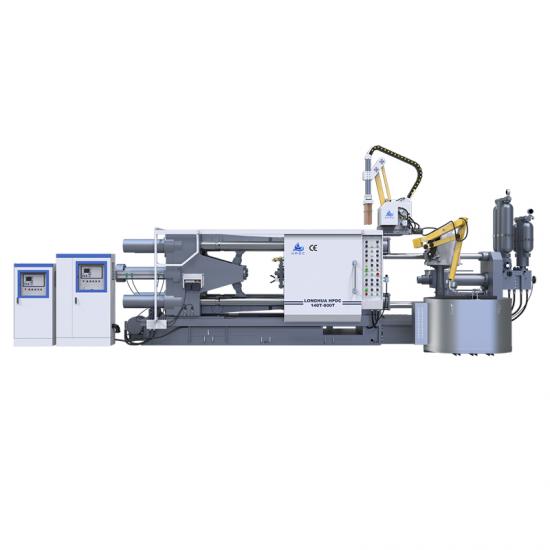

Metal parts horizontal cold chamber die casting machine has the following characteristics:

1. Hile structure: The horizontal design makes the operation of the die-casting machine more convenient, and it

is also conducive to handling heavy workpieces and reducing the labor intensity of workers.

2. Cold room die casting: Compared with the hot chamber die casting, cold chamber die casting is more suitable for

handling high melting point metals such as aluminum alloy. By heating metal alloys in advance, the metal is

placed in a cooling room before injection to liquefy, which helps reduce the formation of metal gases and bubbles,

and improve the density and surface quality of the castings.

3. High pressure injection: Cold chamber die-casting machines usually have high injection pressure, which can

ensure that the metal alloy is fully filled in the mold cavity, ensuring the accuracy and integrity of the casting.

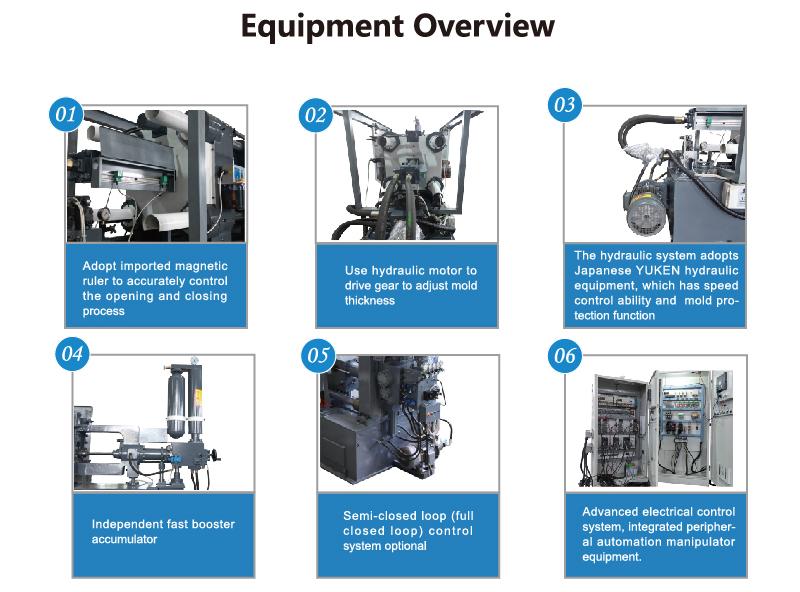

4. Automation control: Modern cold room die casting machines are usually equipped with advanced automation

control systems that can achieve automated operations of the entire production process and improve production

efficiency and consistency.

5. Fast replacement of molds: The cold chamber die-casting machine is usually designed to quickly replace the mold,

so that it can meet the production needs of different shapes and sizes and improve the flexibility of production.

6. Low energy consumption: Compared to the hot room die casting, the cold chamber die casting machine usually uses

energy more effectively, because the metal heated in the cooling room in advance, reducing the waste of energy.

Specification

| LH series of standard parameter table (630 t) | ||

| ITEMS | Unit | Specification |

| Clamping Force | KN | 6300 |

| Opening stroke | mm | 650 |

| Die thickness(Min--Max) | mm | 350~850 |

| Space between tie bars | mm | 750*750 |

| Ejector stroke | mm | 150 |

| Ejector force | KN | 315 |

| Injection position(0 as center) | mm | 0,-250 |

| Injection force(intensification) | KN | 590 |

| Injection stroke | mm | 600 |

| Plunger diameter | mm | ¢70 ¢80 ¢90 |

| lnjection weight(aluminum) | Kg | 7.2 |

| Casting pressure (intensification) | MPa | 153/117/92 |

| Max. casting area(40Mpa) | CM2 | 1575 |

| Injection plunger penetration | mm | 250 |

| Diameter of pressure chamber flange | mm | 130 |

| Height of pressure chamber flange | mm | 15 |

| Max.working pressure | MPa | 14 |

| Motor power | Kw | 30 |

| Dimensions (L*W*H) | m | 8*2.2*3 |

| Machine lifting reference weight | T | 25 |

| Oil tank capacity | L | 1050 |

(Due to the continuous progress of science and technology,the picture,parameter configuration,etc,

will not be changed without notice)

HAKKIMIZDA

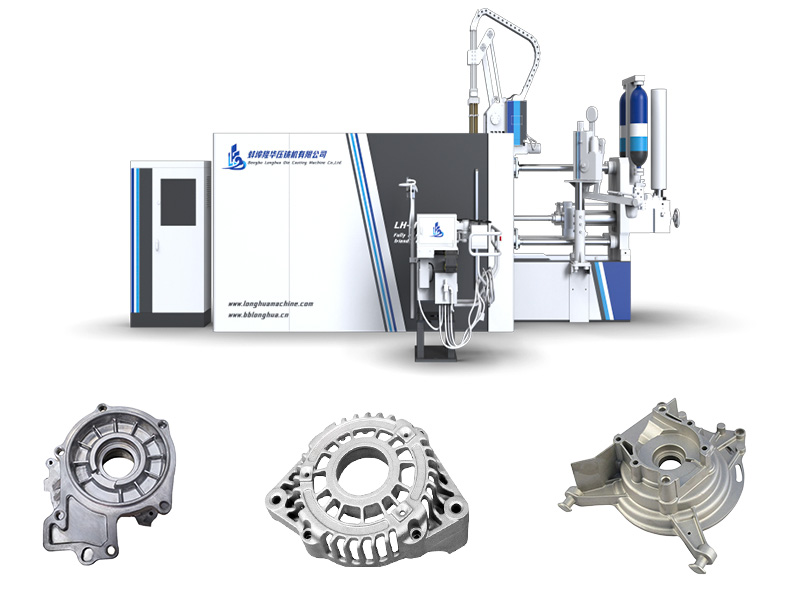

Bengbu Longhua Basınçlı Döküm Machine Co.,Lid, Çin'in Anhui Eyaleti, Bengbu Şehri merkezli bir şirkettir.

Basınçlı döküm makineleri ve ilgili ekipmanların üretiminde uzmanlaşmıştır. 1982 yılında kurulan Longhua Basınçlı Döküm Machine Co., Ltd , onlarca yıldır

basınçlı döküm endüstrisinde yer almaktadır. Şirket , çeşitli basınçlı döküm makinelerinin araştırma, geliştirme, üretim ve satışına odaklanmaktadır. Şirketin ürün yelpazesi soğuk havayı kapsamaktadır. Farklı müşterilerin ihtiyaçlarını karşılamak için odacıklı döküm makineleri, basınçlı döküm manipülatörleri, endüstriyel robotlar ve basınçlı döküm makinelerinin çevresel ekipmanları .