| Type | LH-165KG |

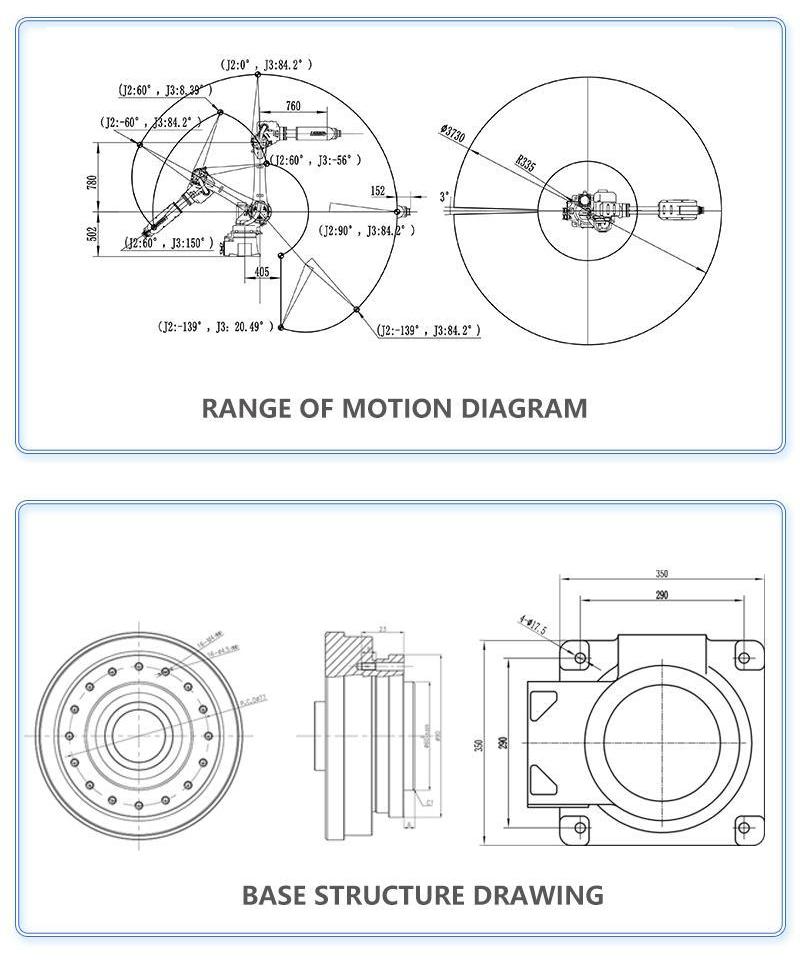

| Axes | 6 |

| Load | 165 Kg |

| Weight | 1200 Kg |

| Reach | 2750 mm |

| Position repeatability | ±0.01 mm |

| Ingress Protection | IP54 |

1.LH-165KG is capable of continuous spot welding and rapid short-distance displacement,and can achieve fast movement of 50mm displacement within 0.5s.

2.LH-165KG has a slim wrist which is very suitable for spot welding in the body compartment.

3.LH-165KG is equipped with dress package,which makes the welding cable and hose (water/gas)closely attached to the robot body,effectively reduces space interference,cable wear and splashing damage,very suitable for automobile spot welding with high movement complexity.

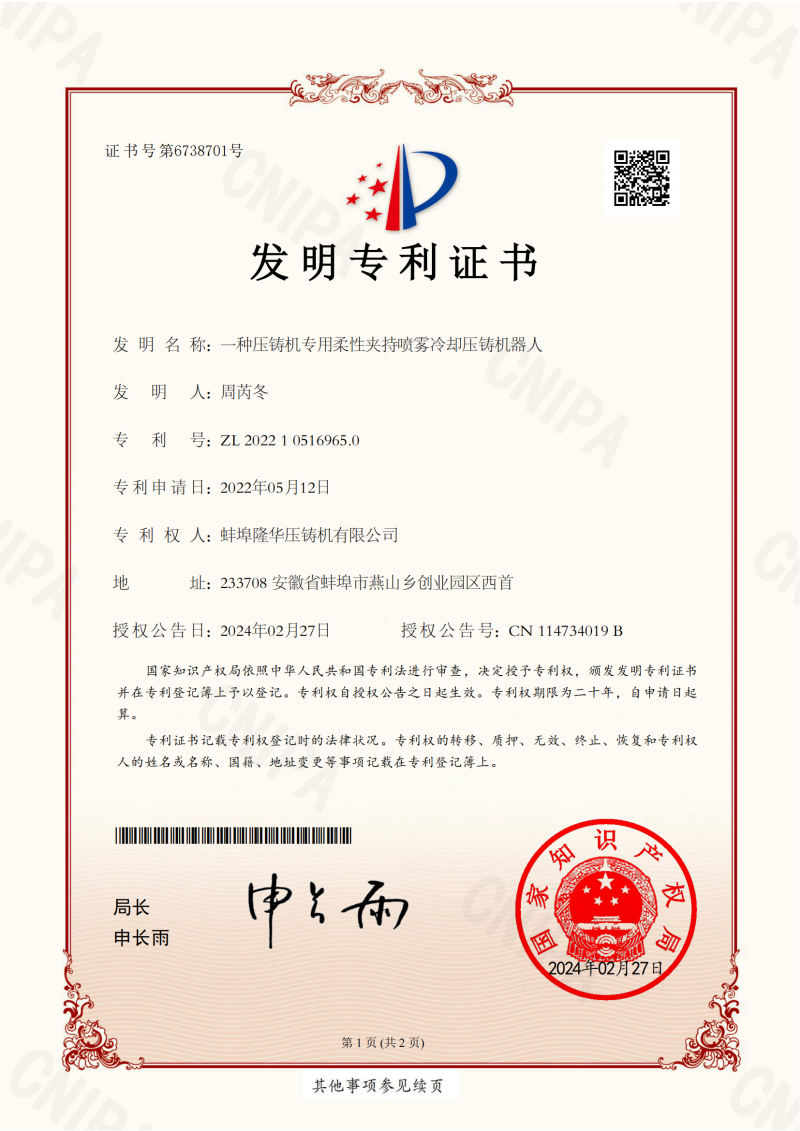

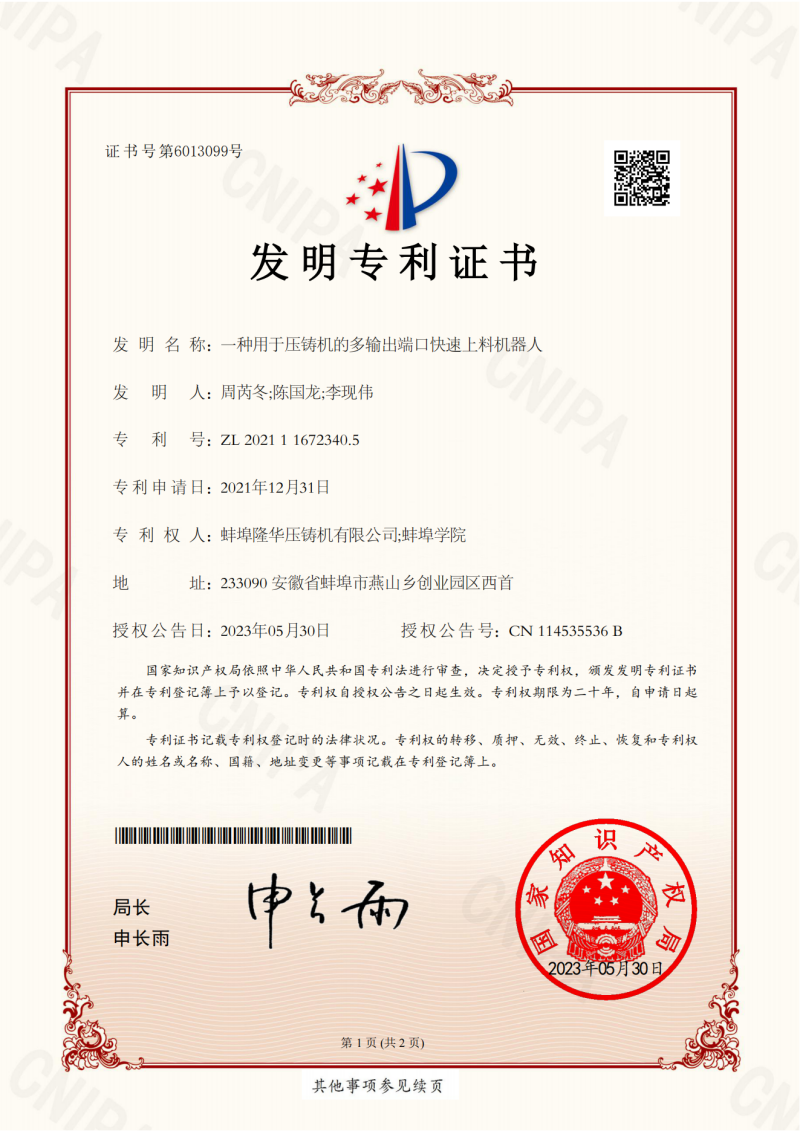

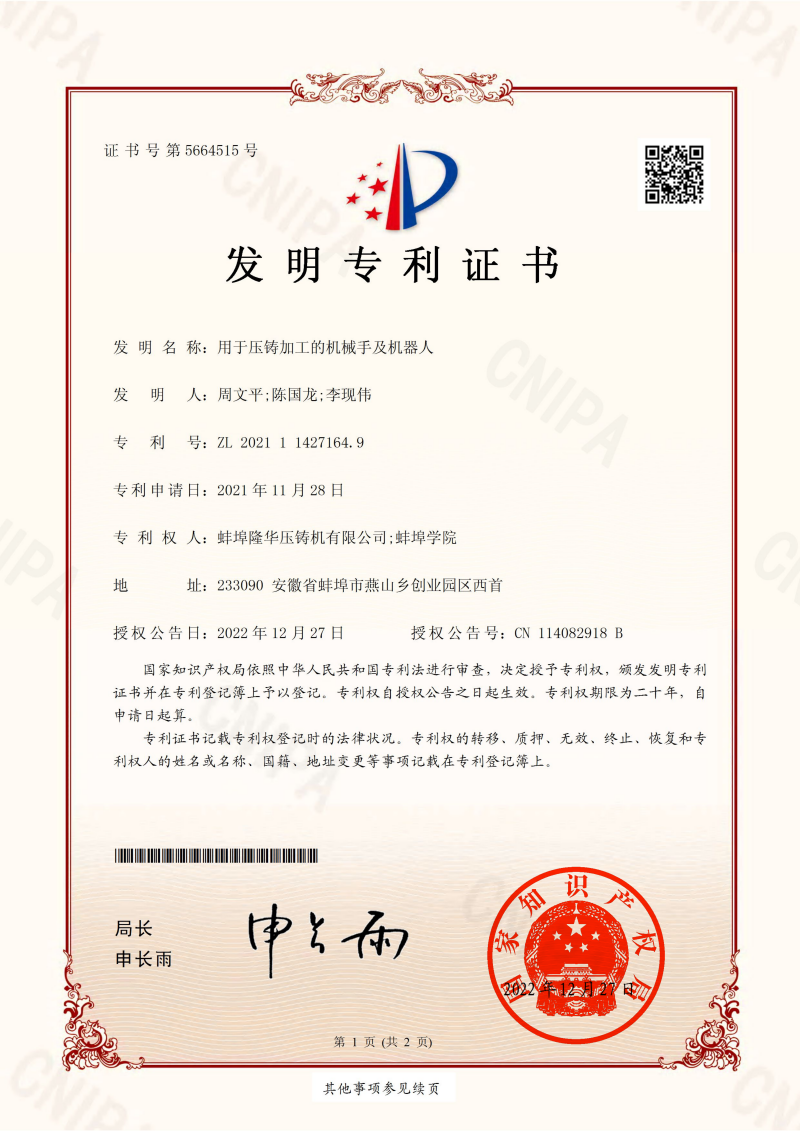

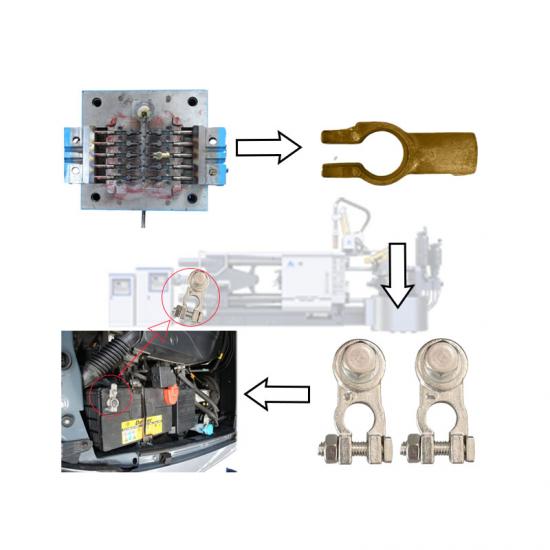

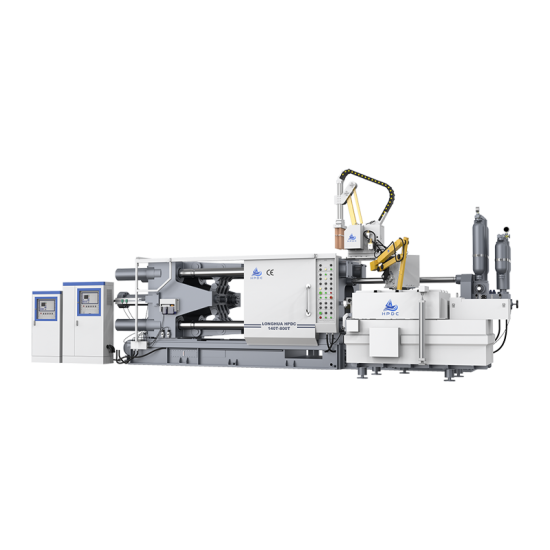

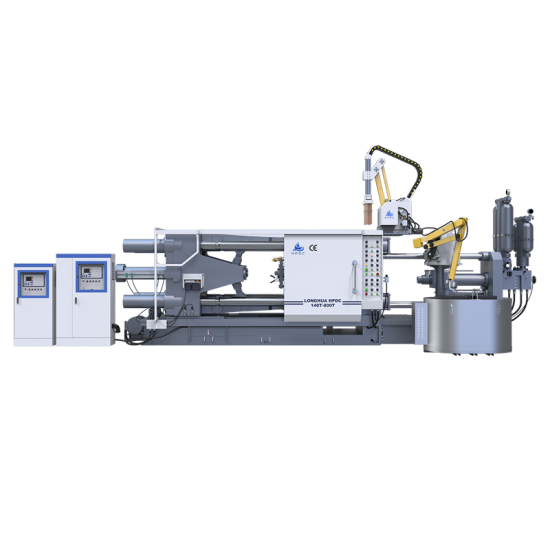

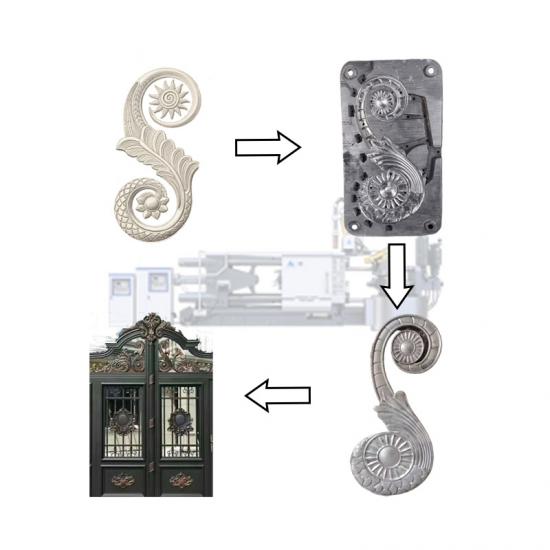

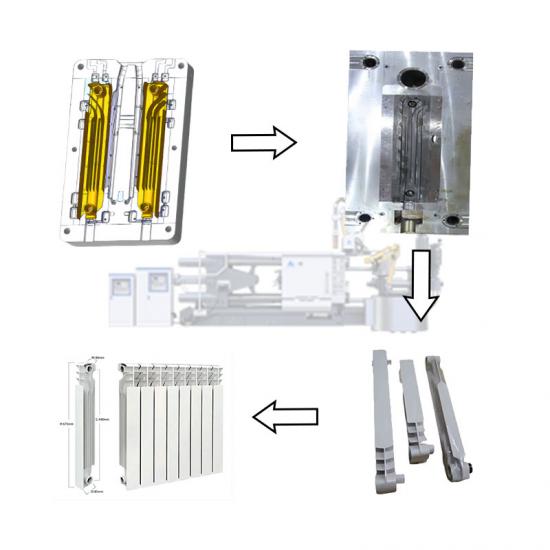

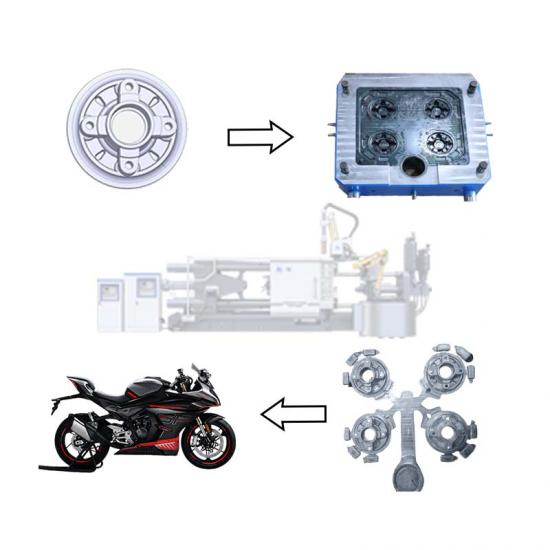

Die casting robots have many important uses in die casting production lines, mainly including the following aspects:

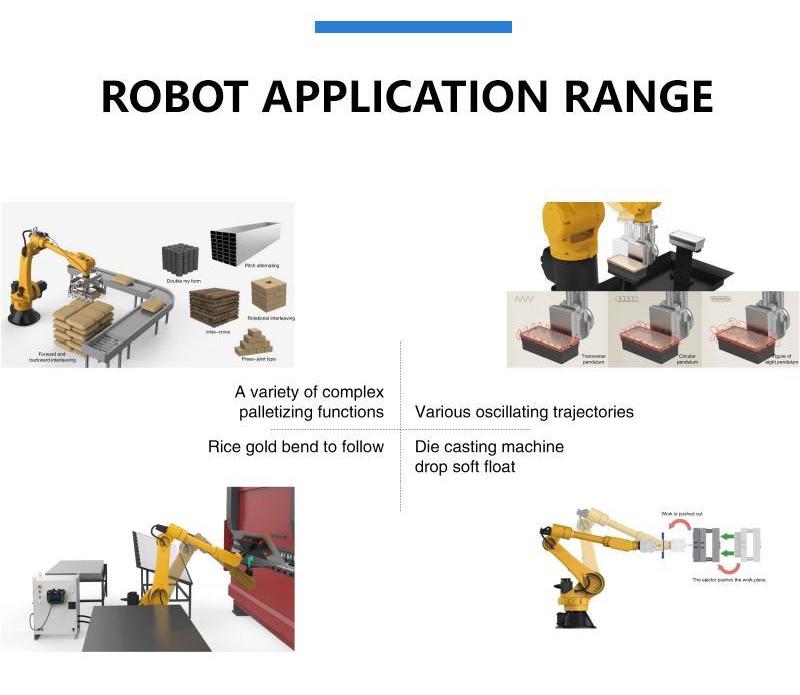

Automatic loading and unloading: Die casting robots can automatically feed raw materials (such as aluminum alloy) into the die casting machine and remove the finished product from the mold after the die casting is completed. This improves production efficiency and reduces the labor intensity of manual operation.

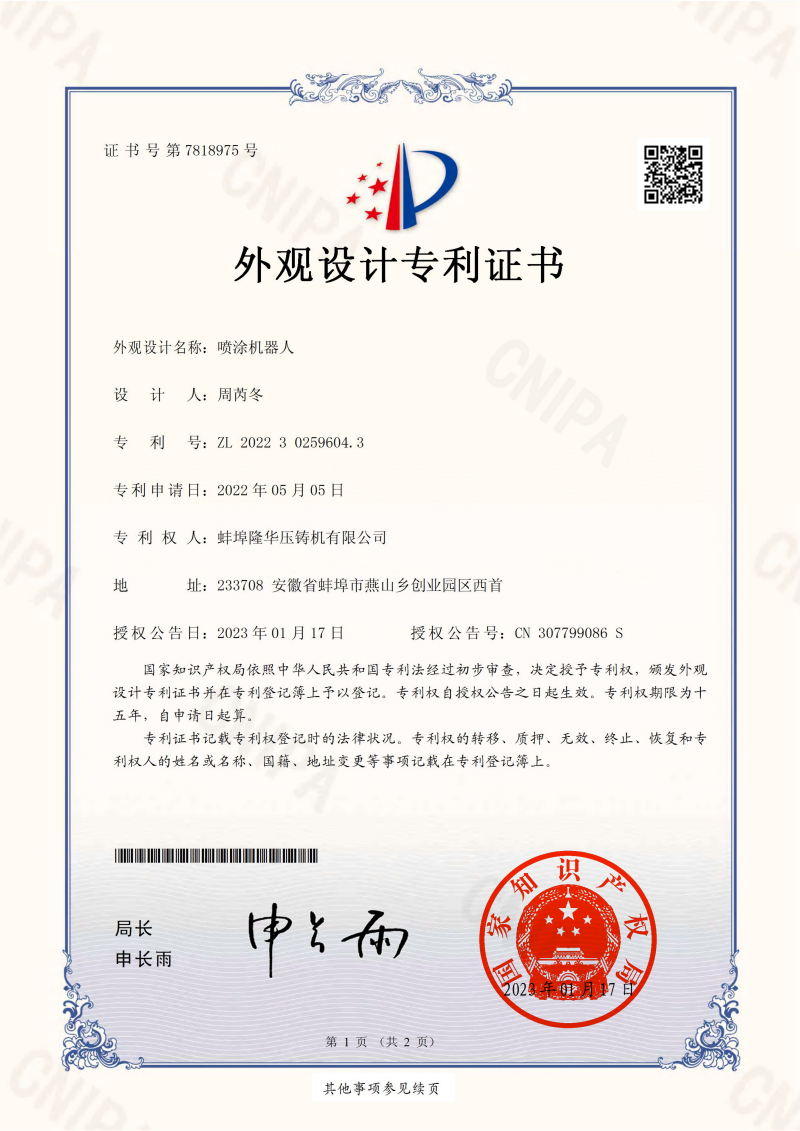

Mold spraying: During the die casting process, the mold needs to be sprayed with lubricants or release agents regularly. Die-casting robots can complete this task accurately, ensuring uniform spraying, extending the life of the mold and improving product quality.

Product transfer and stacking: Die casting robots can transfer die-cast products to designated locations for cooling, inspection or further processing. They can also neatly stack products on pallets or conveyor belts for subsequent processing.

Quality inspection: Some die casting robots are equipped with visual inspection systems, which can perform rapid appearance and size inspections after the product is taken out, identify defects and unqualified products, and thus improve the efficiency of product quality control.

Deburring and trimming: Some burrs and excess edges may be generated during the die casting process. Die casting robots can use special tools to deburr and trim to ensure that the product surface is smooth and flat.

Mold replacement: Some advanced die casting production lines use robots to automatically change molds, which improves the flexibility and switching efficiency of the production line and adapts to the needs of multi-variety and small-batch production.

Data collection and monitoring: Modern die casting robots are usually equipped with sensors and data collection systems, which can monitor various parameters in the production process (such as temperature, pressure, time, etc.) in real time, helping operators to optimize process parameters and improve production stability and product consistency.

Through these functions, die casting robots not only improve production efficiency and product quality, but also reduce the danger of manual operation, improve the working environment, and meet the development trend of industrial intelligent manufacturing.

HAKKIMIZDA

Bengbu Longhua Basınçlı Döküm Machine Co., Kapak, Bengbu Şehri, Anhui Eyaleti, Çin merkezli bir şirkettir. Basınçlı döküm makineleri ve ilgili ekipmanların üretiminde uzmanlaşmıştır.

1982 yılında kurulan Longhua Basınçlı Döküm Machine Co., Ltd, onlarca yıldır basınçlı döküm endüstrisinde yer almaktadır. Şirket, çeşitli basınçlı döküm makinelerinin araştırma, geliştirme, üretim ve satışına odaklanmaktadır. Şirketin ürün yelpazesi soğuk havayı kapsamaktadır. Farklı müşterilerin ihtiyaçlarını karşılamak için odacıklı döküm makineleri, basınçlı döküm manipülatörleri, endüstriyel robotlar ve basınçlı döküm makinelerinin çevresel ekipmanları.